RESEARCH AND DEVELOPMENT

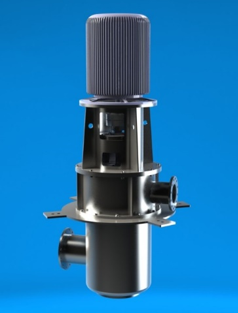

SM PUMPS R&D continuously performed research activities to improve pump hydraulic performances, flow conditions and rotor – dynamic pump characteristics.

Design and development of pumps for Nuclear and Oil&Gas application is based on serious research works on following:

- •Flow conditions through the pumping hydraulic channel, pressure and velocities distribution, vortices

- •Cavitation research

- •Recirculation study

- •Stability

- •Stress, thermal and fatigue analyses

- •Vibration, noise analyses

Requirements for pumps for nuclear power plants are very high and very specific. Design criteria should provide high reliability and high performance of the pumps.

API 610, ISO 13709 international standards specifies requirements for pumps for petroleum, petrochemical and natural gas industry.

Requirements for pumps for other application usually consider basic design requirements with some additional requirements.

PUMPS for NUCLEAR and OIL & GAS APPLICATION

Safety Reliability Performances

| Standards and Regulations Nuclear Code |

| International Atomic Energy Agency |

| National Nuclear Energy Commission |

| National Nuclear Energy Commission |

| ASME Code, ANSI Code, ASTM Code |

| ANSI Code |

| Hydraulic Institute Standards |

| American Petroleum Institute Standards |

| Other end user requirements |

| Design Criteria for heavy duty process pumps |

| Basic Hydraulic requirements and conditions for normal operation |

| Stress limits |

| Normal operating conditions |

| Abnormal operating conditions |

| Emergency conditions |

| Faulted operating conditions |

| Pressure – temperature limits |

| Stress, thermal and fatigue analyze |

| Relibility characteristcs |

| Failure Mode and Effects Nanalyzes |

| Mechanical shock |

| Seismic Requirements |

| Flow reate – vibration mode |

| Flow rate – stability mode |

| Noise and Acoustic Quieting |

| Hydraulic Instabilities |

| Rotor and Rotor Shaft characteristics |